-

Welcome to visit Jiangsu Senmetal Decoration Materials Co., Ltd website

National Service Hotline+86 18071729009

Welcome to visit Jiangsu Senmetal Decoration Materials Co., Ltd website

INTRODUCTION

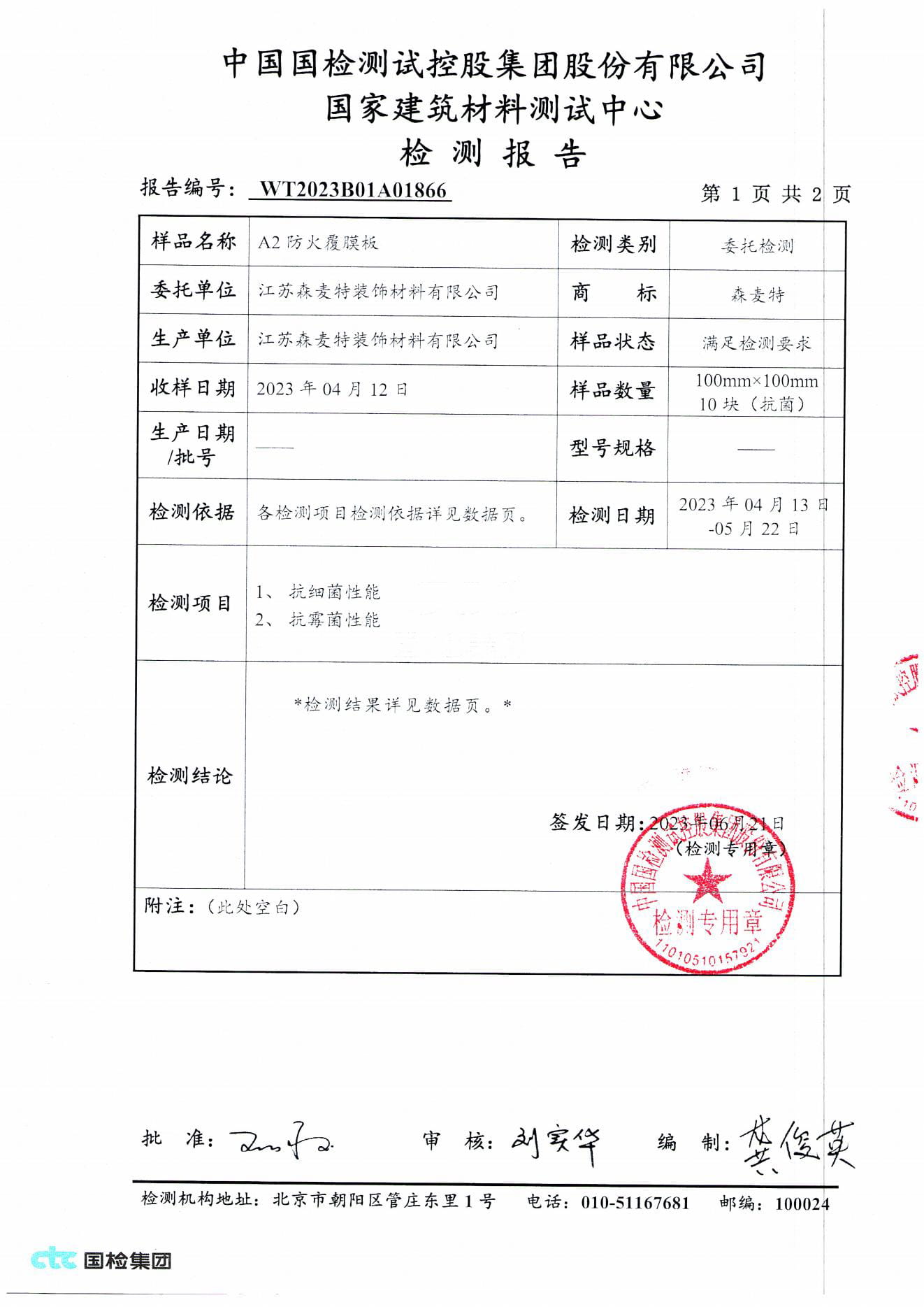

QUALIFICATION

CULTURE

MANUFACTURE

CONTACT

Coated metal composite panel is a new type of material that combines the base layer of metal composite panel with (PP, PVC) environmental protection decorative film after processing. The product has the characteristics of fire resistance (fire class B and class A), moisture-proof, environmental protection 0 formaldehyde, anti-fouling and scratch resistance, easy installation, etc., and is a new decorative material for wood and has a strong competitive advantage in the field of interior and exterior decoration with extensive use of wood veneer. It is suitable for use in large public buildings such as office buildings, commercial spaces, hospitals, star-rated hotels, airports and subways.

Using the company's own research and development of fireproof inorganic core materials, equipped with various types of metal plates, combined with a variety of industry-leading coating processes, is a new type of decorative material with health, environmental protection and safety, its unique fireproof and high temperature resistance can also be done in a specific environment for punching, arc bending and other modeling treatment, adding a unique artistic charm to architectural decoration.

In the process of forming double-sided bumps, under the action of stress between the points, the coiled aluminum metal sheet forms the middle layer core material of the semi-dimple shell-like continuous bridge arch structure, and the upper and bottom aluminum coils are compounded to form a full-dimensional (directionless) evenly stressed aluminum plate. Its reliable physical structure has more advantages than the uneven longitudinal and horizontal stress of corrugated aluminum plate, the low flat compressive strength of honeycomb aluminum plate and multi-dimensional aluminum plate with single-sided convex points, the single finish of aluminum veneer, the difficulty of manual processing and quality control, and the poor fire performance of aluminum-plastic panel.

The metal honeycomb panel is sandwiched with aluminum alloy honeycomb as the sandwich, using high-quality aluminum plate as the panel, and is compounded by hot pressing process, which has excellent characteristics such as light weight, environmental protection, and no deformation, and has Class A fire performance. The surface color is changeable, and the texture is delicate, which is suitable for shopping malls, office buildings, airports and other high-demand sanitary partition places.

acres

Floor space㎡

Modern factory buildingmillion

The total investment is 250 million yuanmillion square

Annual output of fireproof core materialsmillion

The annual output value is 700 millionseries

4 series of productslines

15 production lines.million square

Annual output of A2 grade fireproof composite panels

Strong R&D technical team

Leading R&D technology team in the industry, continuously improving product performance and developing ultimate products to meet the ever-changing market needsA complete and efficient supply chain system

Perfect supply chain collaboration process and mechanism, quickly coordinate and match supply and demand, achieve lean management, and create value for customersFast service responsiveness

7 * 24-hour tracking response, with a service network covering over 30 core cities in China, providing customers with stable and reliable good services

SENMETAL Classroom | Oxidized coloring of aluminum

A layer of oxide film (AlO) is generated on the surface of aluminum and its alloy products by artificial methods and applied with different colors to improve the wear resistance of aluminum, prolong the service life and increase the color and beauty.

2023-05-17

SENMETAL Classroom | Advantages of Class A fireproof aluminum composite panel

Class A fireproof aluminum composite panel is a new type of high-grade wall decoration non-combustible safety fireproof material, with non-combustible inorganic material as the core material, outer composite alloy aluminum plate...

2023-05-17

SENMETAL Classroom | The development prospect of anodizing processing manufacturers

In recent years, anodized titanium electrodes have been used to fill igneous rock with magnetic alloys or with magnetic manganese steels such as iron, cobalt, nickel and manganese steel, and this titanium electrode filling film has magnetic bands.

2023-05-17

Corporate Purpose

Provide customers with cost-effective solutions, Make them trust SENMETALCorporate Values

Customers always come first Integrity, collaboration, struggle, innovation, and progressCorporate Vision

Becoming a leader in the "domestic A-level fireproof material manufacturer" Address: No. 70, Beijing Road, Wuxi-Xinyi Industrial Park, Xinyi City, Jiangsu Province

Address: No. 70, Beijing Road, Wuxi-Xinyi Industrial Park, Xinyi City, Jiangsu Province